- Windows

- Android

- Linux

- Ubuntu

- Vesa Mount

- Embedded Mount

- Panel Mount

Table of Contents

Custom Industrial Displays: Pain Points & Proven Solutions

In today’s industrial landscape, the demand for custom industrial displays is growing rapidly. From manufacturing floors to outdoor transportation hubs, standardized screens no longer meet harsh environmental needs or unique workflow requirements. Decision-makers in Europe, North America, and other global markets are now prioritizing tailor-made display solutions that improve uptime, enhance user interaction, and support long-term operational reliability.

This article breaks down the key pain points faced by international industries and explains how custom industrial displays deliver the right solutions.

1. Harsh Environments Damage Standard Displays

Pain Point:

- Factories, logistics hubs, mining fields, and offshore energy sites expose devices to:

- Dust, oil, debris

- Water spray or humidity

- Vibration and shock

- Extreme heat or freezing temperatures

Commercial displays fail quickly under these conditions, causing expensive downtime and frequent replacements.

Solution: Ruggedized Custom Industrial Displays

A custom industrial display can be built with:

- IP65–IP69K front protection

- Anti-vibration and shock-resistant housing

- High-temperature or wide-temperature components

- Conformal coating for PCB protection

- Optional stainless steel housing for corrosive environments

These features ensure stable operation whether installed in food processing plants, offshore platforms, or outdoor kiosks.

2. Outdoor Visibility Issues Affect Productivity

Pain Point

Outdoor or semi-outdoor operations in the U.S. and Europe struggle with:

- Sunlight glare

- Washed-out screens

- Low contrast

- Poor visibility for operators or customers

This affects safety, transaction accuracy, and user experience.

Solution: High-Brightness, Optically Bonded Displays

A customized industrial display can include:

- 1,000–1,800 nits high-brightness panel

- Optical bonding to eliminate internal reflections

- Anti-glare / anti-UV coating

- Auto dimming sensor

- Wide viewing angles

These provide clear visibility for EV charging stations, outdoor kiosks, smart lockers, and marine control panels.

3. Inconsistent Mounting & Space Constraints

Pain Point

Different machines, kiosks, cabinets, or control consoles rarely share the same mounting dimensions. Off-the-shelf displays do not fit correctly, leading to:

- Costly mechanical modifications

- Unstable installation

- Safety risks

Solution: Custom Mounting & Mechanical Engineering

Custom industrial display manufacturers can deliver:

- Bezel customization

- Open-frame structures

- Panel mount, VESA, rack mount, or flush mount

- Tailored cutout dimensions

- Ultra-thin options for kiosk integration

This reduces integration time and allows seamless mechanical fit for any equipment.

4. Compatibility Problems With Industrial Systems

Pain Point

Legacy machines and modern systems vary widely in I/O and communication protocols. Commercial displays cannot adapt to:

- RS232 / RS485 industrial communication

- CAN bus

- Multi-PC or multi-controller connections

- Custom video inputs (HDMI, DP, VGA, LVDS, etc.)

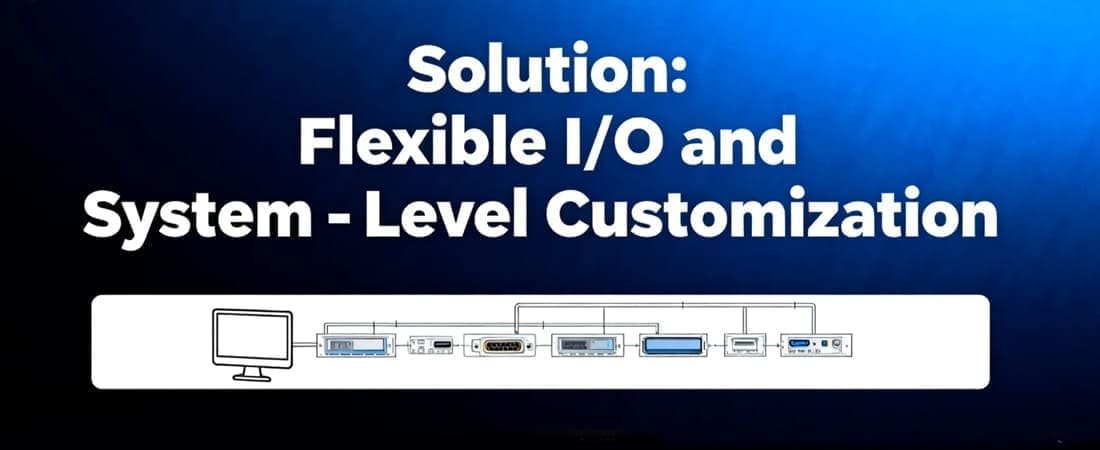

Solution: Flexible I/O and System-Level Customization

Custom display solutions offer:

- Configurable serial ports

- Multi-I/O support

- Legacy system compatibility

- Custom board design (LVDS, eDP, or TTL)

- Touch tuning for gloves, water droplets, or thick cover glass

This ensures smooth integration with AGVs, PLCs, medical equipment, and automation machines.

5. Branding Requirements for Kiosks & Consumer-Facing Devices

Pain Point

For kiosk manufacturers in North America or Europe, branding and user experience matter. Off-the-shelf displays limit design freedom.

Solution: Fully Customized Aesthetics & UX

Manufacturers can customize:

- Front glass printing

- Logo silk-screen

- Bezel color & material

- Custom UI-optimized touch responses

- Specific aspect ratios (4:3, 16:9, square, bar-type, etc.)

This enables OEMs to build differentiated products for retail, ticketing, hospitality, and transportation.

6. Need for Long Product Lifecycle Support

Pain Point

Commercial displays change frequently, creating supply chain instability. Industrial deployments need long-term availability — often 5–7 years or longer.

Solution: Long-Lifecycle Component Planning

Custom industrial display suppliers provide:

- 5–10 years panel availability planning

- Component locking

- Stable supply chain management

- End-of-life (EOL) forecasting and alternatives

This ensures consistent production for large-scale deployments.

7. Specialized Touch Requirements for Industrial Environments

Pain Point

Standard touchscreens fail when users wear gloves, touch with wet hands, or encounter contaminants.

Solution: Tailored Touch Technologies

Custom display engineering can include:

- Glove touch

- Water or droplet rejection

- Sensitivity tuning

- Projected capacitive or resistive selection

- IK-rated impact-resistant cover glass

This is essential for medical, manufacturing, and outdoor kiosk applications.

Conclusion

For global OEMs, system integrators, kiosk manufacturers, and industrial equipment builders, adopting custom industrial displays is not a luxury — it is a direct response to real operational pain points.

If you are looking for a reliable customized industrial display, please feel free to contact us.

FAQs for Custom Industrial Displays

1. What is a custom industrial display?

A custom industrial display is a tailor-made screen designed to operate in harsh industrial environments, with specific size, brightness, touch technology, and mounting options to fit unique equipment or kiosk requirements.

2. Why do industrial environments need custom displays?

Harsh conditions such as dust, vibration, extreme temperatures, and moisture require ruggedized, durable displays that standard commercial screens cannot withstand.

3. Which industries commonly use custom industrial displays?

They are widely used in manufacturing, logistics, oil & gas, energy, medical equipment, transportation systems, and self-service kiosks in Europe and North America.

4. Can custom industrial displays be used outdoors?

Yes. High-brightness panels, optical bonding, anti-glare coatings, and weatherproof housing make them suitable for outdoor kiosks, EV charging stations, and smart lockers.

5. What customization options are available?

Options include screen size, brightness level, touch technology, housing materials, mounting methods, I/O interfaces, cover glass thickness, and color or logo customization.

6. Can custom displays integrate with legacy industrial equipment?

Yes. They can support RS232, RS485, CAN bus, VGA, LVDS, and other legacy interfaces to ensure compatibility with older machines.

7. Are custom industrial displays suitable for kiosk manufacturers?

Absolutely. Custom displays enable perfect mechanical fit, optimized touch performance, and branded front glass—ideal for self-service kiosks and digital vending machines.

8. Do custom industrial displays support glove or wet-hand touch?

Yes. Touch sensitivity can be tuned for gloves, water droplets, thick cover glass, or specialized industrial usage.